Fully recyclable barrier film

While high demands are placed on the functionality of the packaging to protect the food, the end-of-life recycling infrastructure also requires the packaging to be as simple as possible to ensure recyclability. Materials that are not compatible with the main polymers will jeopardise recyclability. For PP films, the focus is particularly on the EVOH barrier layer, which is required if oxygen exchange and flavour loss are to be prevented.

- Adaptation of the film design: The film design was adapted in accordance with the RecyClass recyclability assessment principles, the guidelines of the retail chains and the criteria of the sorting companies.

- This includes reducing the use of EVOH to below 5% without compromising the barrier effect of the packaging.

- Thanks to the existing recycling infrastructure for PP packaging, the optimised barrier film can be seamlessly integrated into the recycling process.

This reference project illustrates how targeted product development and adaptation of the film design can help to improve the recyclability of packaging solutions while maintaining performance and quality.

Testimonials

Coffee capsules

made from bio-based film

Consumers not only require the coffee to be sustainable, but also the packaging. Together with our partners, we have therefore developed a coffee capsule film made from renewable raw materials and brought it to market maturity.

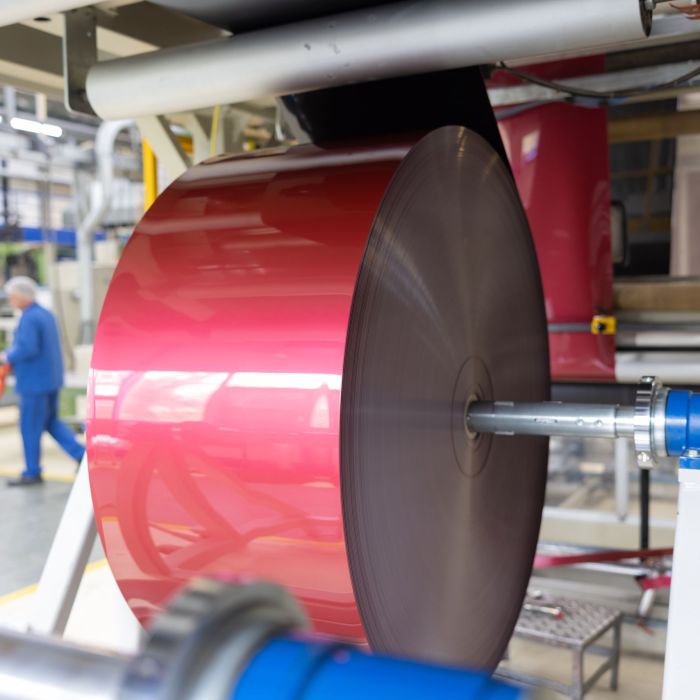

Recyclable PP film

replacing metallised PET

How do you replace a vapour coated APET film with a more recyclable alternative? We have developed a recyclable polypropylene film that retains the eye-catching look and characteristic colour of the packaging.