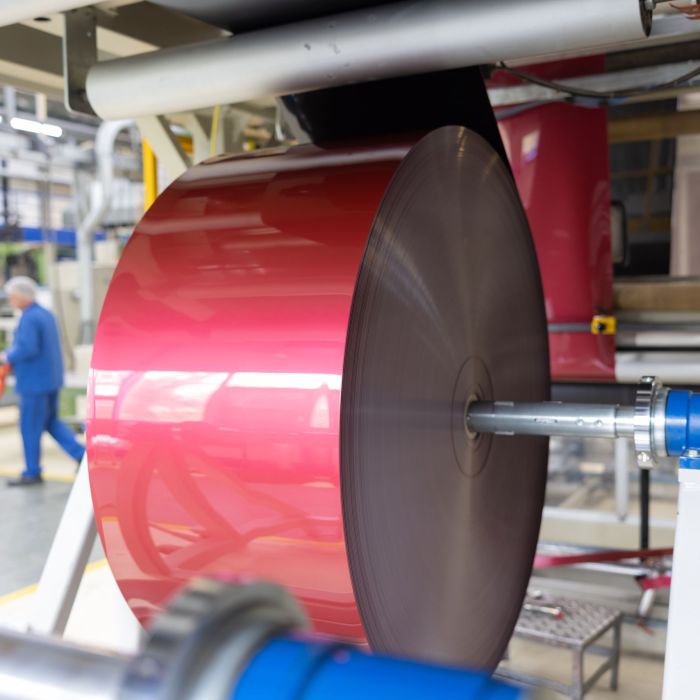

Coffee capsules made from bio-based film

The requirements for films for coffee capsules are particularly demanding, as they are exposed to high temperatures and pressures in coffee machines. These high quality requirements were now coupled with the need to significantly improve the CO2 footprint of the coffee capsules without compromising the performance of the coffee capsules.

-

Tall oil, a by-product from paper production, was chosen as the renewable material for PP production. As a bio-circular material, tall oil does not compete with food production

-

The PP produced from tall oil corresponds 100% to the known PP from fossil sources in terms of product properties. Quality and processability are therefore guaranteed

-

All companies involved in the value chain are ISCC Plus certified, so that the use of the renewable material can be fully proven to the distributor and can therefore also be used in marketing to consumers.

The use of renewable materials not only creates a positive environmental impact, but also brought considerable added value for the end customer. This helped to strengthen the brand image and created competitive advantages as more and more consumers favour sustainable options.

Testimonials

Fully recyclable

barrier film

The recycling infrastructure demands packaging that is as simple as possible so that it can be recycled. ALMA Packaging has further developed the highly functional barrier film so that it can be recycled like mono packaging film.

Recyclable PP film

replacing metallised PET

How do you replace a vapour coated APET film with a more recyclable alternative? We have developed a recyclable polypropylene film that retains the eye-catching look and characteristic colour of the packaging.