About us

Swiss Plastic Sheet Supplier ALMA Packaging

Plastic sheet supplier ALMA Packaging combines many years of experience in the development and manufacturing of multi-layer plastic sheets and films with a profound commitment to sustainability. As a renowned plastic film manufacturer from Switzerland, we offer quality, reliability, and a positive working environment – to the benefit of our customers and partners. We are increasingly using eco-friendly solutions in the production of our plastic sheets and films. Thanks to a wealth of experience, we have already achieved numerous product innovations in the field of sustainable films and are constantly improving the recyclability of existing products.

Our aim is to continue on this successful path. As a leading plastic film manufacturer, we are committed to developing the sustainable packaging solutions of tomorrow – together with our customers and partners. Moreover, we strive to offer plastic sheet and film solutions for new fields of application through technical innovations.

Experienced

manufacturer

Customised

solutions

Sustainable

film

First-class

film quality

Extrusion

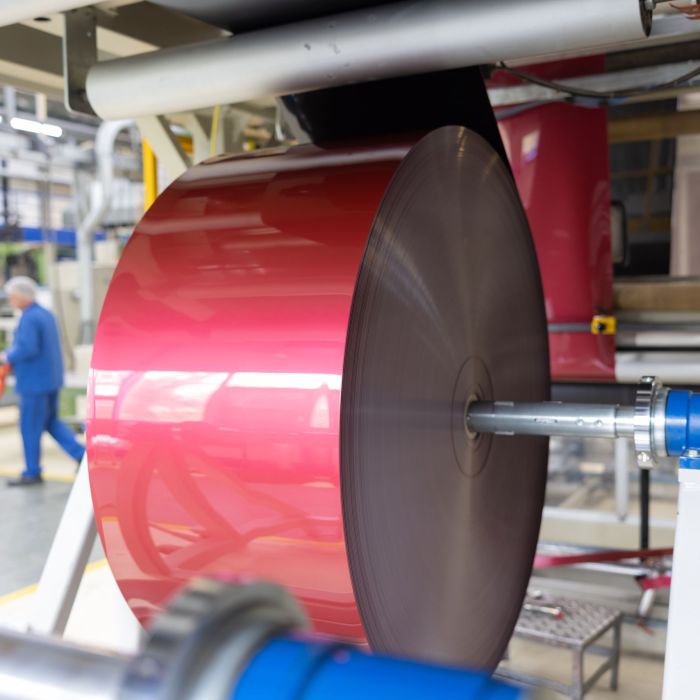

As a Swiss plastic sheet supplier that manufactures a wide range of polymer sheets and films, both our headquarters and production site are located in Cormagens. Here you will find our entire infrastructure – including the laboratory, warehouse, and plastics production. We operate four extrusion lines with a total capacity of up to 10,000 tonnes per year. Uncontaminated production waste is recycled to save raw materials.

Product Development

At ALMA Packaging we have a track record in the development of innovative and highly functional packaging films in co-operation with renowned FMCG partners. On request, our company can develop a customised, market-ready plastic sheet or film of the highest quality for your packaging in the shortest possible time. This is made possible by our agile team and competent organisation.

Laboratory

In our modern and fully equipped laboratory, we validate the quality of our plastics and supply of input material and carry out tests for new developments. This way, we ensure that each product fulfils the individual design requirements – such as pressure and temperature resistance as well as optical, mechanical, and barrier-specific properties.